Our detection system is designed to recognize airborne silica, which can be extremely harmful to the lungs. In fact, the Greeks and Romans realized centuries ago how damaging silica dust was. Silica dust is widely created in construction, maritime and general industry.

Identifier S1

Personal and Stationary Monitoring

Silica is used in large quantities in many different industries and it is easily inhaled. It can cause a range of respiratory ailments, among them asthma, pulmonary tuberculosis and lung cancer. Fortunately, stricter exposure limits are set to take effect in the US in 2018, but this is not the case everywhere.

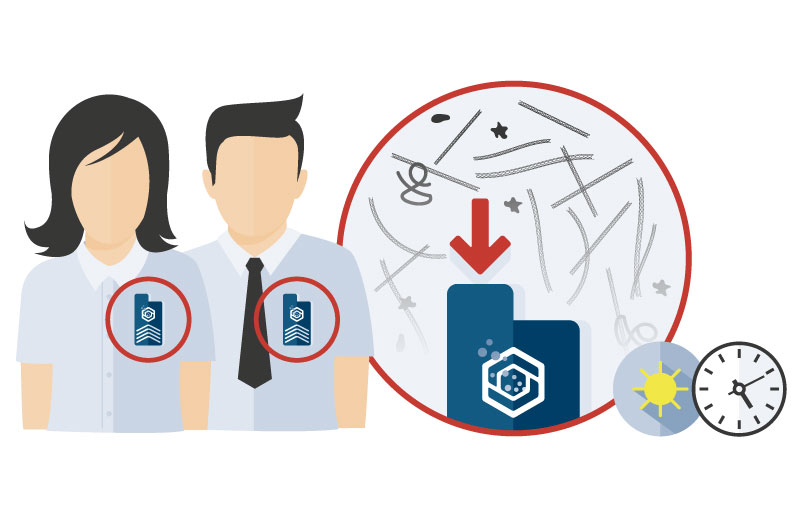

At Stat Peel, we have developed a compact badge sensor and an integrated bench-top sized optical reader to monitor personal occupational exposure to silica to ensure that safe limits are being enforced. It works in two steps:

1. The employees wear lightweight badges during their workday. The badge collects the respirable fraction of airborne silica using an inertia-based size separator on a custom functionalized membrane.

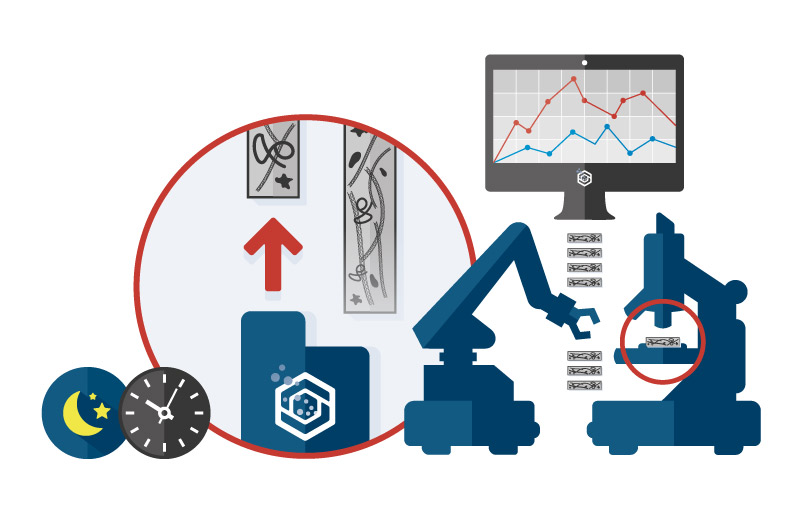

2. At the end of a shift the badges are inserted into the reader, which selectively detects silica using Raman spectroscopy and reports and stores personal exposure.

Components

The badge

Badges can be worn by employees to monitor personal exposure, as well as placed in specific locations within a facility to monitor release. Each badge is about the size and weight of a phone, so it is easy to wear throughout the workday. There is a small opening that allows air to flow through to the filtration slide.

Filtration slides

Filtration slides with specially developed membranes are used to gather particles from the filtered air. Each slide has one, two or three membranes to collect the respirable particle fraction. The appropriate number of membranes is determined by how “clean” a facility is. Each slide has a barcode so it can be traced to a certain user, and the slides can be archived to provide an additional record of compliance.