The large surface area of nanofibers and nanoplatelets can increase the storage capacity and reduce the weight of batteries and capacitors, making them ideal materials for the battery industry.

The demand for electrical mobility and off-grid solar power are among some of the drivers for the massive growth in the use of nanomaterials in those industries.

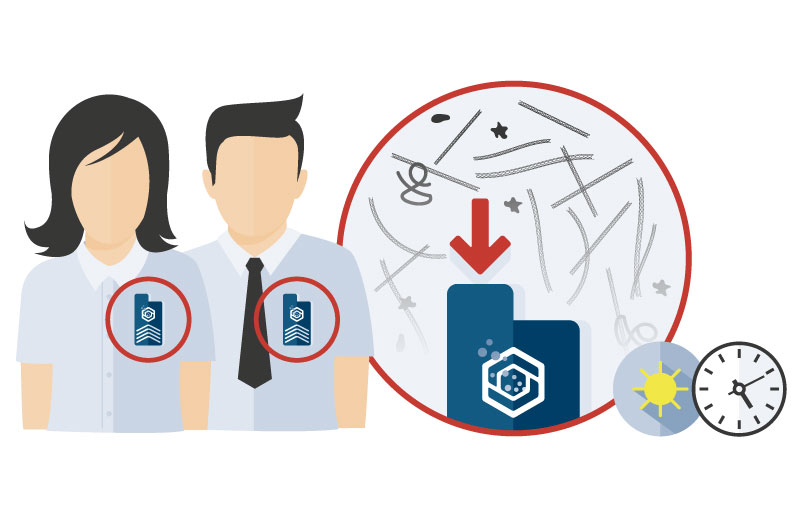

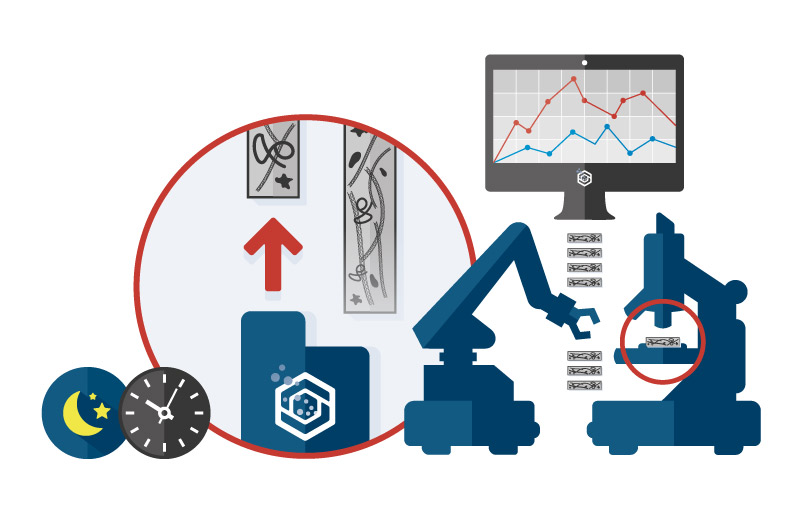

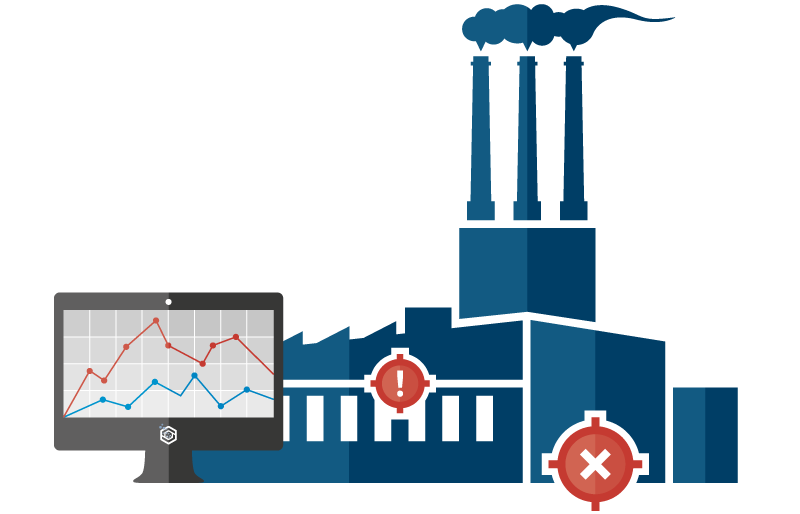

Potential exposure is possible in different life cycle stages, from development and testing to cell production and manufacturing and finally, in recycling.