Our detection system is designed to recognize cellulose nanocrystal, which ongoing research shows can be harmful if inhaled. Although it is derived from wood and considered a green material, its size and shape make it potentially dangerous because it is easy to breathe in.

Identifier N1

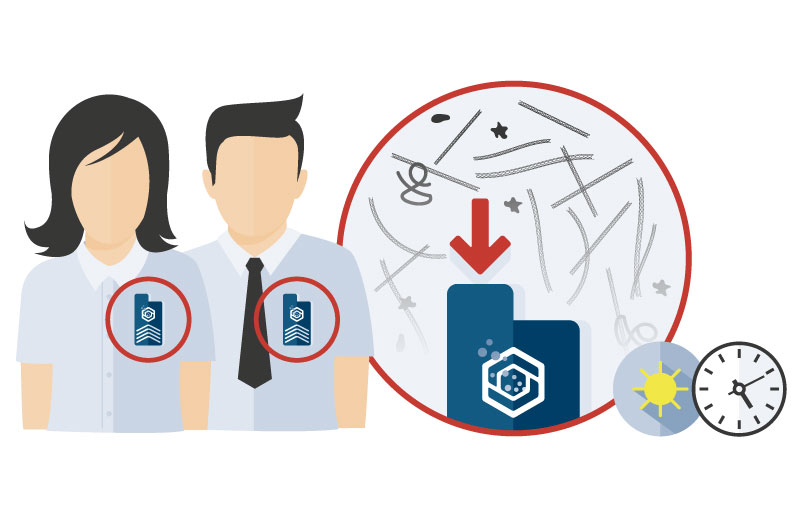

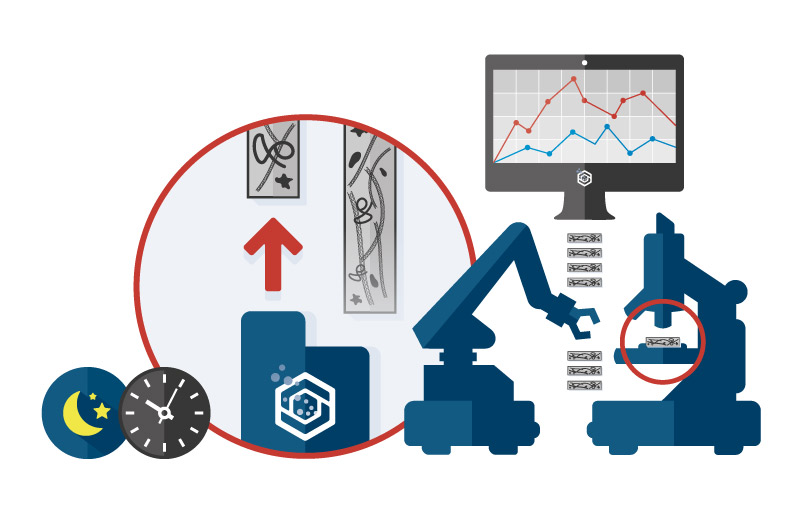

Personal and Stationary Monitoring

At Stat Peel, we have developed a compact badge sensor and an integrated bench-top sized optical reader to monitor personal occupational exposure to nanocellulose fibers. It works in two steps:

1. The employees wear lightweight badges during their workday. The badge collects the respirable fraction of airborne nanocellulose fibers using an inertia-based size separator on a custom functionalized membrane.

2. At the end of a shift the badges are inserted into the reader, which selectively detects nanocellulose fibers using the most advanced Raman spectroscopy and reports and stores personal exposure.

Components

The badge

Badges can be worn by employees to monitor personal exposure, as well as placed in specific locations within a facility to monitor release. Each badge is about the size and weight of a phone, so it is easy to wear throughout the workday. There is a small opening that allows air to flow through to the filtration slide.

Filtration slides

Filtration slides with specially developed membranes are used to gather particles from the filtered air. Each slide has one, two or three membranes to collect the respirable particle fraction. The appropriate number of membranes is determined by how “clean” a facility is. Each slide has a barcode so it can be traced to a certain user, and the slides can be archived to provide an additional record of compliance.